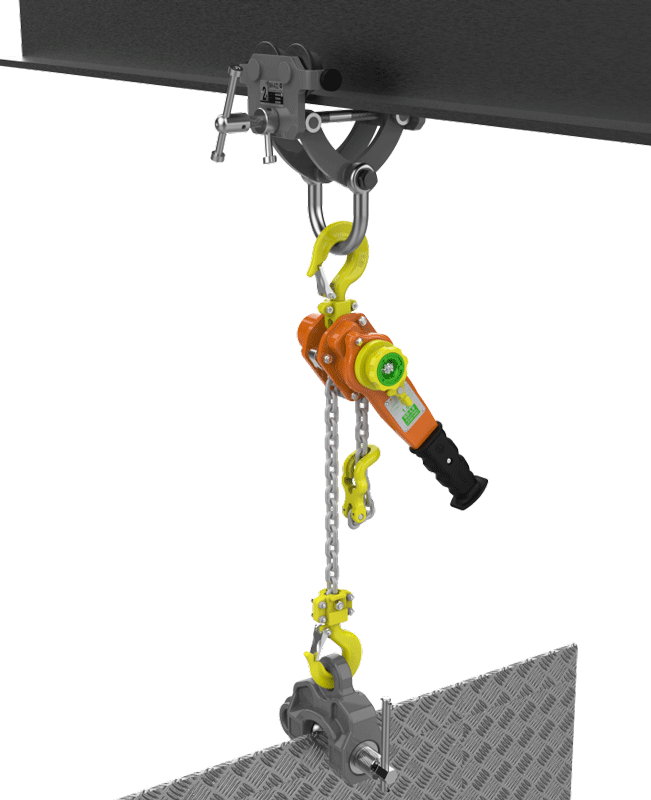

Subsea Lever Hoist – Hacketts SSL5

The model range of the Hacketts SSL5 subsea lever hoist starts at 0.8 tone capacity and goes up to 15 tonnes. Ideal for subsea and topside lifting, pulling and tensioning applications.

Uses of the Subsea Lever Hoist – Hacketts SSL5

Designed to be operated by a diver when used in submerged applications. Also suitable for use in other lifting and pulling tasks in other marine environments and high moisture areas, thanks to the high corrosion resistant components and waterproof grease used which will help to prevent rusting in harsh, briny conditions. Subsea, dockside, boating, water treatment plants are all common areas of use.

Because this lever hoist can be utilised with cross haul or fleeting angles up to 60 degrees without any de-ration of the capacity required it can be used for a wider range of tasks.

The Hacketts SSL5 subsea lever hoist is made and tested in the United Kingdom by William Hackett and uses high spec components and finishes. Featuring a triple layer Akzonobel marine paint finish with an ISO12944 Category 5 rating (designed to last 7-15 years).

The SSL5 subsea ratchet lever hoist is verified for safe use for a single immersion over a 90 day period or a 60 day period for multi-immersions

SSL5 Subsea Ratchet Lever Hoist Features

The SSL5 ratchet lever hoist has some excellent features with the quad pawl design enhancing its safety. Due to the four pawls, failure is highly unlikely because there will always be at least one pawl engaged. A dual anti-lock brake system enables adjustments to the load chain without the need to lock the brake this is known as the free-wheeling mode.

Much thought has gone into the design process to minimise debris ingress to the brake system. The frictions brake material is sintered and fused to the gear and together with grooves for water flow the risk of diminished brake function is minimal.

The springs on the pawls are made from stainless steel and are situated inside the brake chamber for optimum protection.

Stainless fixings are used throughout and the components have added corrosion protection including disc hub, load sheave, pinion shaft, pawls and stands, ratchet gear, load chain guide, stay bolts and chain stripper.

For more information, specifications and model dimensions please refer to the information and manual PDF downloads in the tab above.

More hoisting options for marine environments

Standard lifting hoists won’t cut it in harsh marine environments whether subsea or topside. The salty atmosphere will rapidly degrade the hoist. Using specialist hoists which are typically termed subsea hoists can help to prevent this rapid degrading through rust. The components, lubricants and finishes are all done in corrosion resistant materials, so subsequently the hoists safety is greatly enhanced; so is the working life of the hoist.

Lever hoists, chain blocks and ROV controlled hoists suitable for these conditions can be found at the Lifting Gear Store in our subsea hoisting equipment category.