Under Braced Jib Cranes

Under braced jib cranes are designed to maximise the lifting height thanks to the placing of the jib arm brace. Custom made to order, typically within 14-21 days (often quicker) our experienced fabricators and team of engineers will manufacture your swing jib to suit your needs. There is a wide range of options available with maximum lifting capacities of 3000kg available to order.

Benefits of Under Braced Jib cranes

Under braced jib cranes are our most popular option for this type of lifting crane. This is largely due to the fact that the crane can go right up to the roof space, thus maximizing the potential height of lift. So if your ceiling height is limited or there are obstacles in the way but you need maximum lifting height then these under braced swing jib cranes are the way to go. They are ideal in factory type settings, ware houses, car garages, engineering facilities, work shops and more.

The under bracing offers the additional support the jib arm/boom requires, however the bracing is welded to the lower edge of the top beam where the trolley and hoist run across. This means that the trolley will stop when it reaches the brace rather than being able to go fully across to the upright column like it can with an over braced jib crane. So the maximum travel distance along the beam will be a little smaller.

Under braced Swing Jib Crane Sizes Available

Firstly lets talk about loading capacity! Our bespoke jibs with under bracing are available in 125kg, 250kg, 500kg, 1000kg, 2000kg & 3000kg lifting capacities, so there is a really good choice.

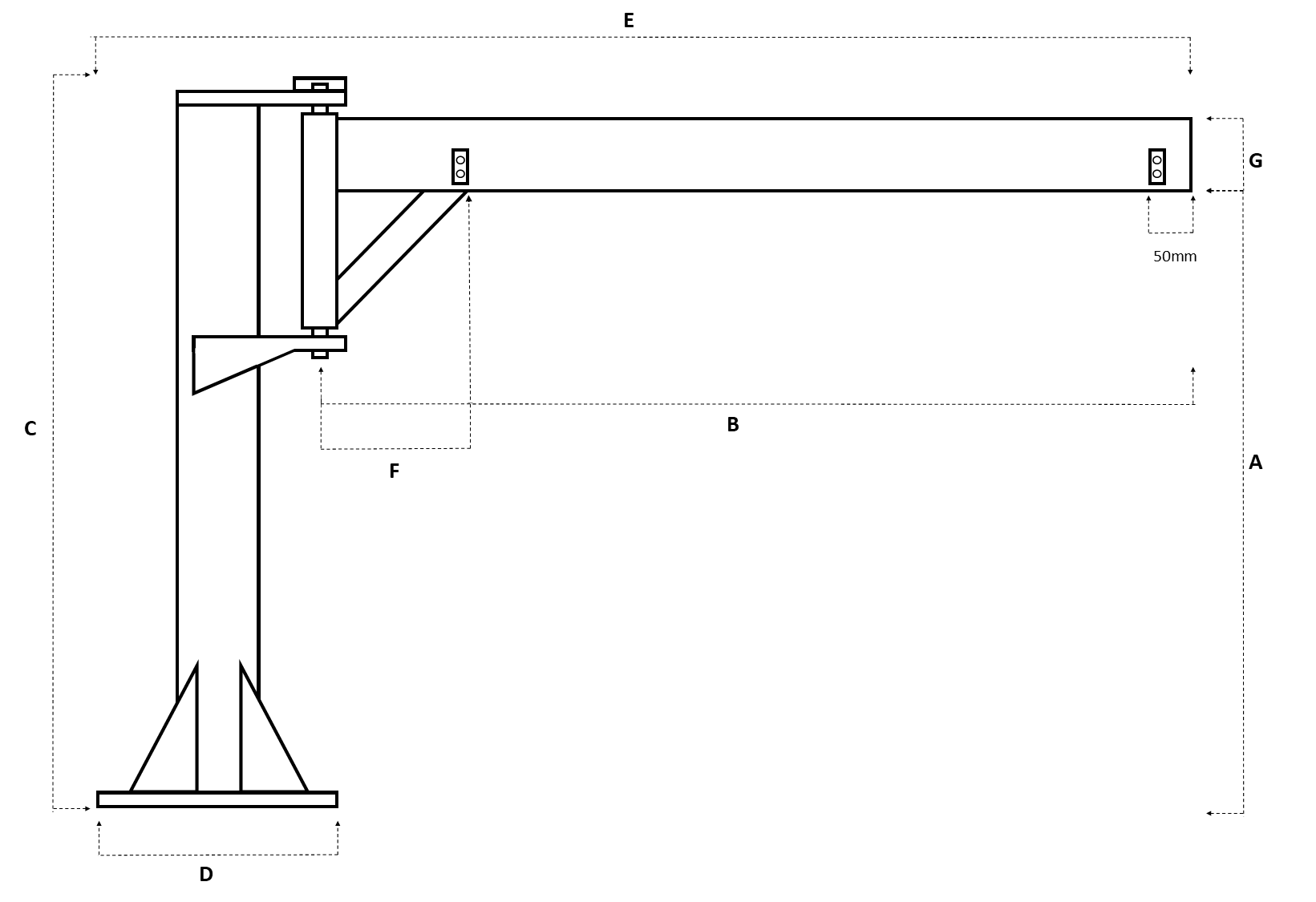

Now lets discuss the height! We always refer to the under beam height when it comes to jib cranes because this is the maximum possible lifting height which is the figure most customers need. Therefore, with this in mind the overall height will be slightly higher to take into account the size of the top beam. This varies between models due to the fact that different sized steel sections are used for different capacities in order to cope with the load safely.

All sizes are available with 3 or 4 metres under beam height, however our 500kg and 1000kg models can be produced to 5 metres if required.

Lastly the jib arm reach needs to be considered. There are a number of measurements to consider here! The overall size from the edge of the column to the tip of the arm, the beam length from the centre of the fixing point to the end of the arm and the maximum beam travel length, (the measurement from the bracing to the tip of the arm). The overall size and the beam travel size are the most important measurements to consider to ensure it will fit into the physical space where you need it and to ensure the beam travel length is sufficient for our load moving requirements.

All models are available with a 3, 3.5, & 4 metre overall radius/reach with the 500kg & 1000kg models also being available up to 5 metres. Don’t forget you will need to deduct the width of the bracing to get the actual beam travel measurement. See all the figures in the specifications above.

Optional Extras to Enhance Your Jib Crane

Enhance your jib cranes even further by adding on one or more of our optional extras.

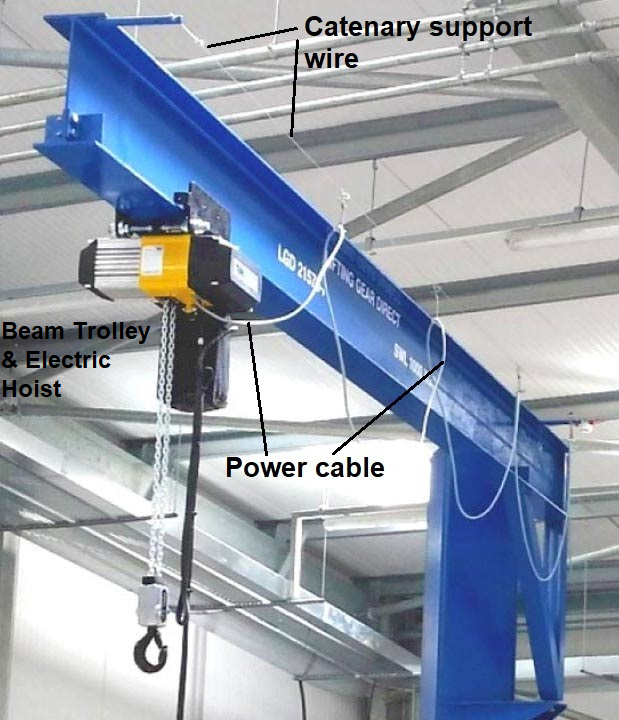

Catenary wires or festoon systems are ideal if you are to be using powered equipment; they hold the cables away from moving components, thus enhancing safety. Isolator switches and/or knockout boxes are also available for further safety enhancement. Our engineers can pre wire your crane ready for electrical equipment.

The Lifting Gear Store can also supply beam trolleys and clamps as well as manual or electric hoists in a range of capacities to compliment your crane.

Our engineers are available to install your custom jib crane which are anchored to the ground with chemically anchored bolts. It is your responsibility to ensure the ground is stable, please get in touch if you need advice.

| 125kg Jib Crane | ||||||||

| Underbeam Height (A) | Arm Radius (B) | Overall Height (C) | Base Plate (D) | Overall length (E) | Brace (F) | Beam Depth (G) | Fixing bolt size* | Max Deflection |

| 3-mtr | 3-mtr | 3209mm | 350mm | 3463mm | 531mm | 152mm | 8 x M20 | 36mm |

| 3.5-mtr | 3235mm | 400mm | 4017mm | 588mm | 178mm | 8 x M20 | 42mm | |

| 4-mtr | 3260mm | 400mm | 4517mm | 646mm | 203mm | 8 x M20 | 48mm | |

| 4-mtr | 3-mtr | 4209mm | 350mm | 3492mm | 531mm | 152mm | 8 x M20 | 48mm |

| 3.5-mtr | 4235mm | 400mm | 4017mm | 588mm | 178mm | 8 x M20 | 56mm | |

| 4-mtr | 4260mm | 400mm | 4532mm | 646mm | 203mm | 8 x M20 | 64mm | |

| 250kg Jib Crane | ||||||||

| Underbeam Height (A) | Arm Radius (B) | Overall Height (C) | Base Plate (D) | Overall length (E) | Brace (F) | Beam Depth (G) | Fixing bolt size* | Max Deflection |

| 3-mtr | 3-mtr | 3260mm | 400mm | 3515mm | 502mm | 203mm | 8 x M20 | 36mm |

| 3.5-mtr | 3260mm | 400mm | 4032mm | 574mm | 203mm | 8 x M20 | 42mm | |

| 4-mtr | 3263mm | 400mm | 4532mm | 646mm | 207mm | 8 x M20 | 48mm | |

| 4-mtr | 3-mtr | 4260mm | 500mm | 3532mm | 502mm | 203mm | 8 x M20 | 48mm |

| 3.5-mtr | 4260mm | 500mm | 4106mm | 574mm | 203mm | 8 x M20 | 56mm | |

| 4-mtr | 4263mm | 500mm | 4606mm | 646mm | 207mm | 8 x M20 | 64mm | |

| 500kg Jib Crane | ||||||||

| Underbeam Height (A) | Arm Radius (B) | Overall Height (C) | Base Plate (D) | Overall length (E) | Brace (F) | Beam Depth (G) | Fixing bolt size* | Max Deflection |

| 3-mtr | 3-mtr | 3263mm | 500mm | 3656mm | 502mm | 207mm | 8 x M20 | 36mm |

| 3.5-mtr | 3313mm | 500mm | 4156mm | 543mm | 256mm | 8 x M20 | 42mm | |

| 4-mtr | 3361mm | 500mm | 4656mm | 588mm | 304mm | 8 x M20 | 48mm | |

| 4-mtr | 3-mtr | 4263mm | 500mm | 3656mm | 502mm | 207mm | 8 x M20 | 48mm |

| 3.5-mtr | 4313mm | 500mm | 4156mm | 543mm | 256mm | 8 x M20 | 56mm | |

| 4-mtr | 4361mm | 500mm | 4656mm | 588mm | 304mm | 8 x M20 | 64mm | |

| 5-mtr | 3-mtr | 5263mm | 500mm | 3656mm | 502mm | 207mm | 8 x M20 | 60mm |

| 3.5-mtr | 5313mm | 500mm | 4156mm | 543mm | 256mm | 8 x M20 | 70mm | |

| 4-mtr | 5361mm | 500mm | 4656mm | 588mm | 304mm | 8 x M20 | 80mm | |

| 5-mtr | 5361mm | 600mm | 5725mm | 732mm | 304mm | 8 x M24 | 100mm | |

| 1000kg Jib Crane | ||||||||

| Underbeam Height (A) | Arm Radius (B) | Overall Height (C) | Base Plate (D) | Overall length (E) | Brace (F) | Beam Depth (G) | Fixing bolt size* | Max Deflection |

| 3-mtr | 3-mtr | 3361mm | 500mm | 3656mm | 443mm | 304mm | 8 x M24 | 36mm |

| 3.5-mtr | 3364mm | 500mm | 4156mm | 514mm | 307mm | 8 x M24 | 42mm | |

| 4-mtr | 3368mm | 600mm | 4725mm | 584mm | 311mm | 8 x M24 | 48mm | |

| 4-mtr | 3-mtr | 4361mm | 500mm | 3656mm | 443mm | 304mm | 8 x M24 | 48mm |

| 3.5-mtr | 4364mm | 500mm | 4225mm | 514mm | 307mm | 8 x M24 | 56mm | |

| 4-mtr | 4368mm | 600mm | 4725mm | 584mm | 311mm | 8 x M24 | 64mm | |

| 5-mtr | 3-mtr | 5361mm | 500mm | 3656mm | 443mm | 304mm | 8 x M24 | 60mm |

| 3.5-mtr | 5364mm | 500mm | 4225mm | 514mm | 307mm | 8 x M24 | 70mm | |

| 4-mtr | 5368mm | 600mm | 4725mm | 584mm | 311mm | 8 x M24 | 80mm | |

| 5-mtr | 5409mm | 900mm | 5825mm | 704mm | 352mm | 8 x M30 | 100mm | |

| 2000kg Jib Crane | ||||||||

| Underbeam Height (A) | Arm Radius (B) | Overall Height (C) | Base Plate (D) | Overall length (E) | Brace (F) | Beam Depth (G) | Fixing bolt size* | Max Deflection |

| 3-mtr | 3-mtr | 3460mm | 600mm | 3725mm | 386mm | 403mm | 8 x M30 | 36mm |

| 3.5-mtr | 3421mm | 800mm | 4430mm | 481mm | 364mm | 8 x M30 | 42mm | |

| 4-mtr | 3517mm | 800mm | 4930mm | 498mm | 460mm | 8 x M30 | 48mm | |

| 4-mtr | 3-mtr | 4460mm | 600mm | 3930mm | 386mm | 403mm | 8 x M30 | 48mm |

| 3.5-mtr | 4421mm | 800mm | 4430mm | 481mm | 364mm | 8 x M30 | 56mm | |

| 4-mtr | 4517mm | 800mm | 4930mm | 498mm | 460mm | 8 x M30 | 64mm | |

| 3000kg Jib Crane | ||||||||

| Underbeam Height (A) | Arm Radius (B) | Overall Height (C) | Base Plate (D) | Overall length (E) | Brace (F) | Beam Depth (G) | Fixing bolt size* | Max Deflection |

| 3-mtr | 3-mtr | 3466mm | 800mm | 3930mm | 383mm | 409mm | 8 x M30 | 36mm |

| 3.5-mtr | 3523mm | 900mm | 4515mm | 422mm | 466mm | 8 x M30 | 42mm | |

| 4-mtr | 3524mm | 900mm | 5015mm | 493mm | 467mm | 8 x M30 | 48mm | |

| 4-mtr | 3-mtr | 4466mm | 800mm | 3965mm | 383mm | 409mm | 8 x M30 | 48mm |

| 3.5-mtr | 4523mm | 900mm | 4515mm | 422mm | 466mm | 8 x M30 | 56mm | |

| 4-mtr | 4524mm | 900mm | 5015mm | 493mm | 467mm | 8 x M30 | 64mm | |