Web Slings

£1.62 – £98.07Price range: £1.62 through £98.07

This type of lifting sling is manufactured from high quality polyester materials and may be referred to as a webbing sling or Duplex sling. We can supply web slings with safe working loads up to 10 tonne for online purchase. With custom slings often available on request. Our double layer Duplex web slings start at just £1.62 for the 1 tonne version.

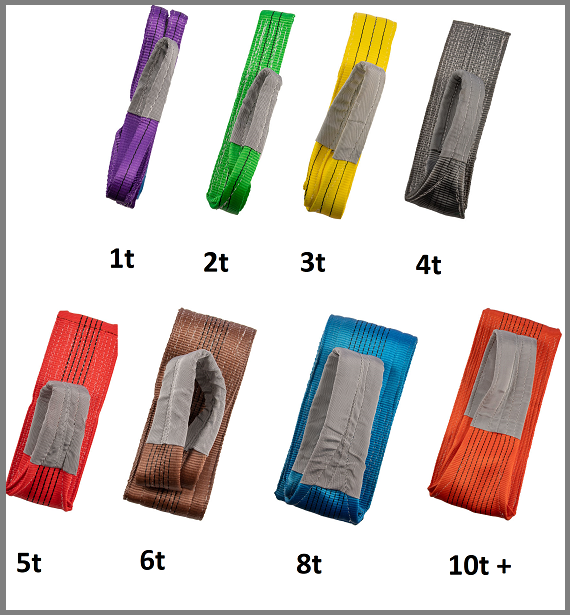

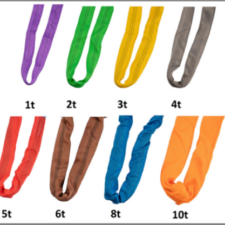

Why are Web Slings Different Colours?

Firstly the web slings supplied at the Lifting Gear Store are fully tested, certified and come in the industry standard colour coded system.

The lifting industry bodies standardised the colour system many years ago in order to quickly and easily identify the safe working load of a sling. This saved much time trying to identify the slings loading values by searching for a small identity label. Or a stamped on mark which has worn off.

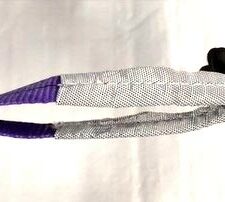

With that said, today every web sling must also have a blue identity label stitched into the sling to comply with more recent regulations.

These blue labels are easy to find and incorporate much more information than just the SWL.

You will find information including;

- the manufacturers details and contact numbers

- Serial number.

- WLL (working load limit)

- The EWL (effective working load)

- materials used

- Conformity standard number.

- CE mark and year

- Manufacture date

- Safety factor

- How the sling may be used (typically in image format) these show hitch types and angles of use.

Web Sling Colours, WLL and Widths

If you use different slings on a daily basis then you should learn the colour codes. Check out the specifications PDF download for an easy to read guide.

1 tonne slings are purple and can be 30 or 50mm wide

2 tonne slings are green and are 60mm wide

3 tonne slings are yellow and are 90mm wide

4 tonne slings are grey and are 120mm wide

5 tonne slings are red and are 150mm wide

6 tonne slings are brown and are 180mm wide

8 tonne slings are blue and are 240mm wide

10 tonne & over are orange and are 300mm wide or more

Web Sling Properties

Manufactured from 100% polyester these high strength Duplex webbing slings are in accordance to BS EN 1492. EC/UKCA declarations of conformity are supplied. Our Duplex webbing slings are lightweight and have low stretch properties so excess elongation shouldn’t be an issue.

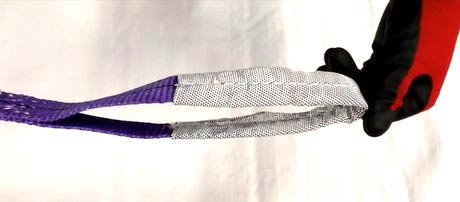

The eyes or loops at each end have added protection, because these are the heavy wear areas, constantly in and out of load hooks. Additional wear sleeves can also be added to any portion on the length of the sling where there is likely to be repetitive excess wear.

These slings are UV and moisture resistant and are suitable for use in temperatures ranging from minus 40 to plus 100 degrees Celsius. Care should be taken when used in areas where chemicals are used. Although polyester is resistant to moderate strength acids they can be damaged by alkali solutions. Any steel fittings used with your sling can also be affected in these situations so be sure to consult the manufacturer. Because some steel grades are susceptible to hydrogen embrittlement from acids.

Safety and Inspection

As with all lifting slings, checking your web slings before use is a must, look for any damage that will affect the sling during use. Keep a look out for cuts, abrasions, surface chafing, loose stitching, weld splatter or other burns, missing labelling information, embedded objects and excess wear. A thorough inspection by a competent person needs to be undertaken at regular intervals to keep your health and safety records up to date.

Here at the Lifting Gear Store you will also find round slings, chain slings and many other types of lifting gear available to buy online with delivery times of typically a day or two. Get in touch if you need any help.

| Weight | 0.25 kg |

|---|---|

| Capacity (sling) | 1 Tonne, 2 Tonne, 3 Tonne, 4 Tonne, 5 Tonne, 6 Tonne, 8 Tonne |

| Length Required (duplex) | 1MTR EWL, 2MTR EWL, 3MTR EWL, 4MTR EWL, 5MTR EWL, 6MTR EWL, 7MTR EWL, 8MTR EWL, 10MTR EWL, 12MTR EWL |