Collared Eye Bolt with Reeve-able Egg Link – Metric & BSW

£11.62 – £44.10Price range: £11.62 through £44.10

Available in both metric and BSW thread types the collared eye bolt with reeve-able egg link is ideal for angular lifting tasks up to 2.75 tonnes.

Collared Eye Bolt with Reeve-able Egg Link Details

Collared eye bolts fitted with a reeve-able egg link enables versatile and reliable angled lifting solutions. These specialized lifting points combine the secure anchoring of a collared eye bolt with the convenience of an integrated egg link.

The collared or shouldered design of this eye bolt reduces the risk of the shank bending, due to the shoulder sitting flush to the mounting surface, thus distributes forces more evenly. This is especially important for angled lifting tasks where the forces are applied to the bolt differently to a straight lift.

The reeve-able egg link moves freely within the eye of the bolt which enables it to pivot towards the line of pull when a sling is attached during lifting operations. The smaller end of the egg shaped link stays at the bottom, in the eye of the bolt, whilst the wider end at the top enables wider slings to be passed through or larger hooks and shackles to be connected. If using webbing type slings you should ensure that it is of a suitable width so that there is no excessive bunching, the sling should be flat.

Eye Bolt with Egg Link – Sizes and Standards

Metric threaded collared eye bolts come in safe working loads from 0.15 t up to 2.5 tons and thread diameters from 8mm up to 24mm.

BSW Whitworth threaded varieties are available in SWL from 0.25 to 2.75 ton, the thread diameters are measured in inches and start at 3/8” to a maximum 1 inch.

Take a look at the specification tables in the tab above to find out all the measurements you need, including the inside of the egg link – an important measurement when deciding what other hardware will be attaching to it.

When it comes to the standards of these eye bolts you can be assured of quality and safety. They haves a safety factor of 5:1, or a minimum breaking load of five times the safe working load.

The dimensions conform to BS4278 – tables 1&4 to ensure consistency across all same type threads.

Manufactured from hardened & tempered steel for the eye bolt and the egg link from high tensile steel. EC declarations of conformity can be provided, as can certification of the raw materials used.

Safety Considerations

Proper installation and usage is essential for safe operation. The collar must seat completely against a flat, smooth surface. The bolt must be tightened to the correct torque, according to the manufacturer’s specifications.

You should always ensure the load direction aligns with the axis of the eye bolt, as side loading can cause issues and reduce safe working capacity. Regular inspection for wear, corrosion, or damage should be part of any lifting equipment maintenance program.

The Lifting Gear Store has a great selection of lifting points to consider including long shank eye bolts, eye and bow nuts and you standard type of eye bolt. Dynamo and collared varieties can be found in either metric or BSW Whitworth sizes.

| Weight | N/A |

|---|---|

| Type/Size/SWL (col-reeve-egg-eyebolt) | Metric / 8mm/ 0.15 ton, Metric / 10mm / 0.25 ton, Metric / 12mm / 0.40 ton, Metric / 16mm / 0.80 ton, Metric / 20mm / 1.6 ton, Metric / 24mm / 2.5 ton, BSW / 3/8 inch / 0.25 ton, BSW / 1/2 inch / 0.5 ton, BSW / 5/8 inch / 0.9 ton, BSW / 3/4 inch / 1.4 ton |

| METRIC Specifications | ||||||

| Safe Working Load | Diameter Thread | Diameter Link | Length Link Inside | Width Link Inside | Thread Length | Weight |

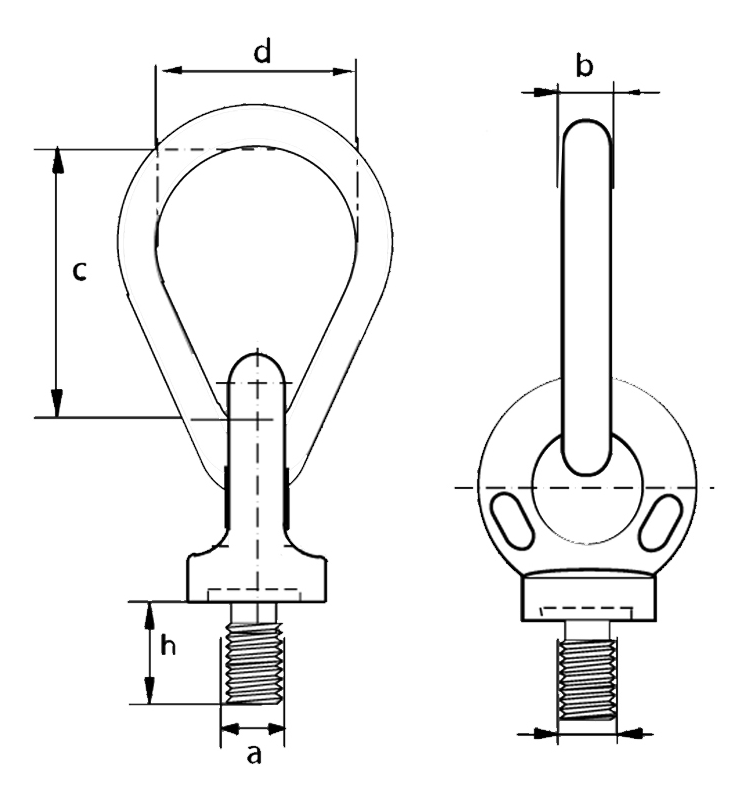

| tonnes | a mm | b mm | c mm | d mm | h mm | kg |

| 0.15 | 8 | 11 | 70 | 35 | 18 | 0.22 |

| 0.25 | 10 | 11 | 70 | 35 | 18 | 0.22 |

| 0.4 | 12 | 11 | 70 | 35 | 18 | 0.23 |

| 0.8 | 16 | 16 | 100 | 50 | 23 | 0.62 |

| 1.6 | 20 | 19 | 120 | 55 | 32 | 1.17 |

| 2.5 | 24 | 25 | 152 | 76 | 40 | 2.66 |

| BSW Specifications | ||||||

| tonnes | a inch | b inch | c inch | d inch | h inch | kg |

| 0.25 | 3/8 | 7/16 | 2.3/4 | 1.3/8 | 18 | 0.21 |

| 0.5 | ½ | 7/16 | 2.3/4 | 1.3/8 | 23 | 0.29 |

| 0.9 | 5/8 | 5/8 | 4 | 2 | 28 | 0.73 |

| 1.4 | ¾ | ¾ | 4.3/4 | 2.1/4 | 35 | 1.19 |

| 2.75 | 1 | 7/8 | 5.3/8 | 2.5/8 | 40 | 2.65 |