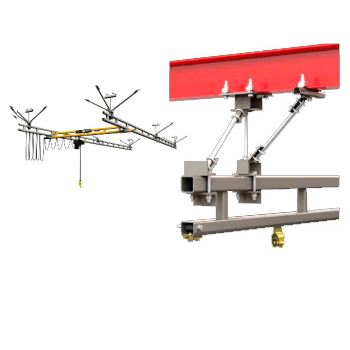

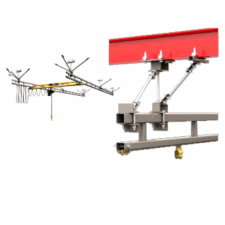

Ceiling Mounted Light Cranes

It is often the case that that factories or workshops simply do not have the necessary space or sufficient foundations to install a typical floor mounted crane system. In these scenarios a ceiling mounted light cranes system should be considered.

Your building structure will need to be assessed to ensure that it is structurally sound and capable of withstanding the imposed forces intended with the ceiling mounted light crane.

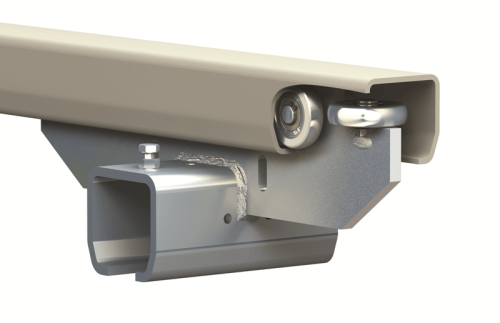

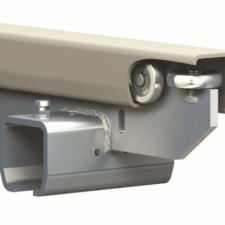

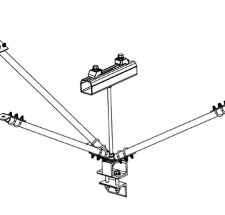

Our range of ceiling mounted light cranes is produced in modular segments with the enclosed track profiles being light in weight yet having high strength properties. The track’s running profile incorporates stand-off reinforcements to enable much larger spans.

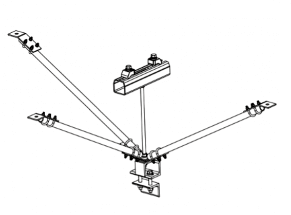

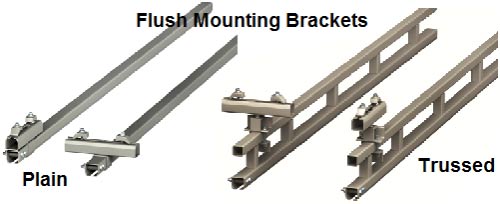

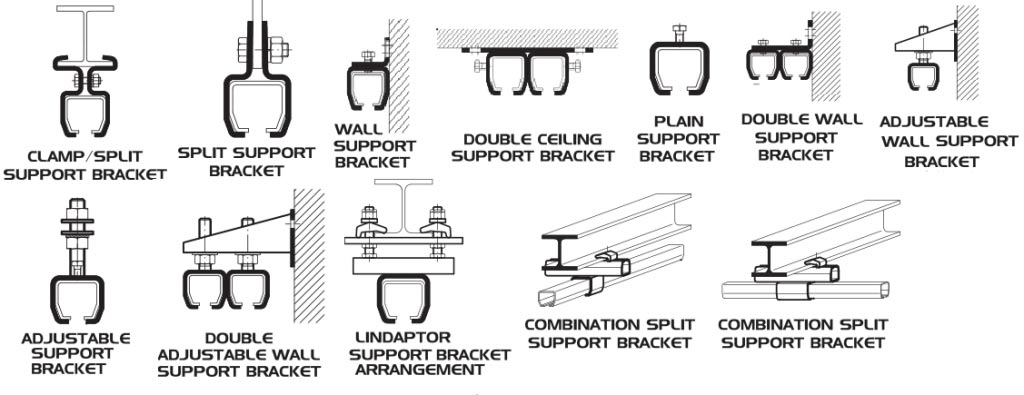

There are a wide range of support brackets options to choose from in order to cover most types of building constructions and supporting steel work, though special sway bracing is usually recommended as well for ceiling mounted light cranes.