A Frame Gantry

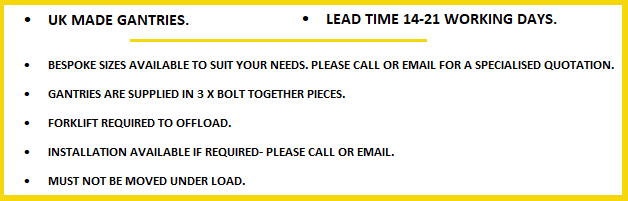

Our A frame gantry systems and mobile gantries as they are often called are made to order in our own factory. This enables full customisation to suit your lifting requirements. The maximum span we manufacture to is 5 metres and up to 5 metre under beam height. These will depend on the safe working load capacity you choose.

Bespoke A frame Gantry

Our A frame gantry systems are manufactured in our own facilities by our long serving fabricators and engineers. We are able to create a bespoke gantry with a range of options to choose from. Parking jacks for added stability are a popular option and ideal when the ground is not level, these come as standard with the 3000kg and 5000kg gantries and must be used when lifting loads. Other options include catenary wires to hold power cables away from moving equipment. Power isolator switches, and possibly colour choice. Another option is that you can choose to have no wheels at all and instead have plated feet. This could be useful if you would like to use it in a single location where, with the use of the floor plates it can be bolted to the floor.

Our gantries come in blue as standard with 2 of the 4 castors incorporating brakes all as standard. Find out more about the options below.

How a Mobile Gantry Crane Works

Mobile gantries are a lifting framework used in lifting applications; they predominantly come in three main parts. Two ‘A’ frame legs and a top cross beam. Cross beams are secured to the top of the ‘A’ frames by 8x grade 8 bolts. These bolts not only enables them to be self erected, but also easily dismantled and put into storage or transported elsewhere in a truck. Four heavy duty, load tested swivel castors are added, 2 of these incorporate brakes and come supplied as standard. All four wheels can be fitted with brakes if you require. These castors enable the gantry to be pushed around to different areas of the workplace where a heavy load needs lifting and moving. The load can be lifted and moved along the beam whilst stationary with the castors locked. You should not attempt to move the gantry around with a suspended load.

Why Use a Mobile A Frame Gantry

An A-frame gantry provides a load bearing framework for lifting heavy loads. They also provide a great substitute to permanently fixed overhead cranes. Fixed cranes need a fair bit of space, and are typically more expensive, what’s more they can be unnecessary for something which may be used infrequently. An A frame gantry is often more cost effective as they are not permanently fixed. When castors are added they are a mobile crane or if they have plated feet and are bolted to the ground they are classed as a semi-permanent crane. They are also fairly easy to move to other locations or into storage if they are not needed, they can be disassembled if required..

Commonly used in a wide range of industrial settings, as well as smaller workshops etc. The impermanence of our gantries means a smaller outlay than a fixed overhead crane. Structural surveying to ensure the building’s stability is not usually needed. If floor mounted you must ensure the floor is solid and able to hold the gantry an loads securely.

Measuring up for your A frame Gantry Crane

When measuring up for a gantry crane we generally ask for the height under the beam measurement and the working span. However if you only have the total height measurement (including the top beam) and/or total span measurements that is fine as we have can precisely calculate both the under beam height and the working span.

It is worth noting that only the largest lifting capacity model of 5000kg can be built with a 5 metre under beam height. For all other models the maximum is 4.5 metres. Typical under beam heights often chosen are 3, 4 or 4.5 metres. Working spans are typically 3, 4 or 5 metres. These are the actual working area sizes (the inner measurements) the outer, overall size will be a little larger depending on the size chosen and the size of steel used which changes according to the safe working load lifting capacity.

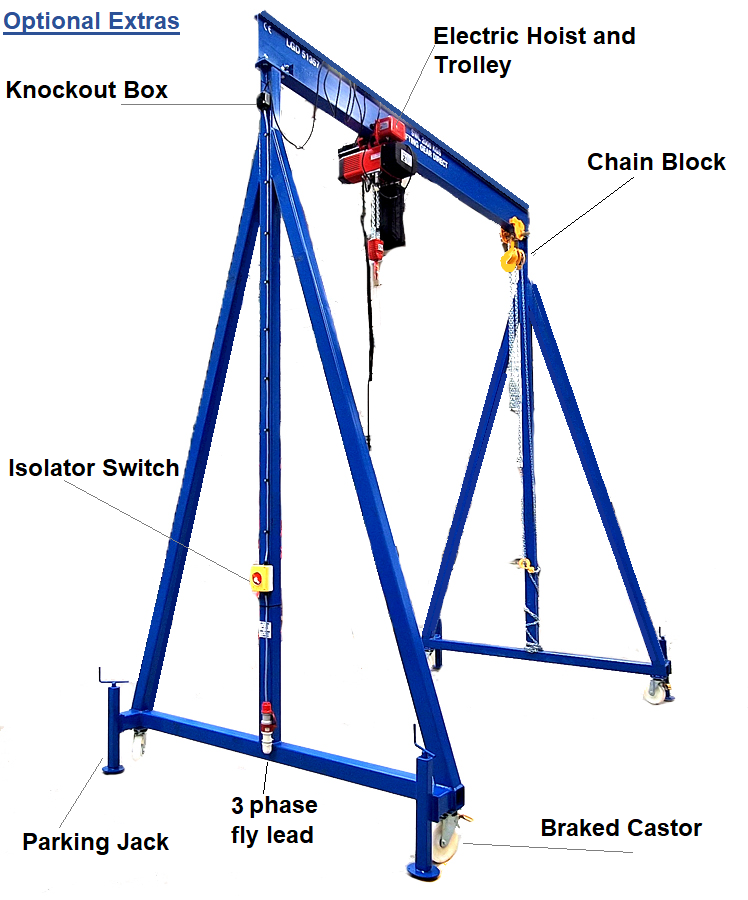

Choosing your Mobile Gantry Options

As mentioned above there are a number of optional extras which can be added onto your gantry during the manufacturing process in order to further enhance the crane. These items help to customise your gantry to make it much easier and safer to use whilst ensuring they work with your specific requirements.

Safe Working Load.

This is the maximum lifting capacity of the crane and is clearly visible on the top beam for quick identification. Never exceed the stated SWL. The Lifting Gear Store can supply A frame gantries in capacities of 500kg, 1000kg, 2000kg, 3000kg and 5000kg as standard.

Parking Jacks

Parking jacks are our most popular add on and provide excellent stability, 3000kg & 5000kg gantries come with these jacks as standard..

If you choose this option the jacks will be welded to the frame near each castor. The jack feet are adjustable and can be wound/screwed up and down so that each corner can be specifically adjusted until the gantry is level. A spirit level will come in handy here.

The benefits of parking jacks are two fold. Firstly if the ground is uneven the jacks enable easy levelling. Secondly jacks add more stability to the gantry as they extend further out from the main frame.

Castors or Plated Feet

Castors enable the gantry crane to be moved around and therefore is ideal for areas where loads need to be lifted in multiple areas. Our mobile gantries come with 2 standard swivelling castors and 2 braked castors which also swivel for easier steering. There is an option to have all 4 castors braked if you would prefer the additional safety. The braked must always be applied for the lifting process to prevent the gantry from moving and getting out of control and/or become unstable and tip.

If you will only be using the crane in one position then you may wish to consider the plated feet option. These can be bolted into the ground for a semi-permanent lifting gantry.

Catenary wires and festoon systems

Catenary systems are where a tensioned wire rope is added to the top beam, extending out somewhat. Festoons systems are where suspenders are attached to the catenary. This system enables power cables from electric hoists and trolleys for example to be safely held out of the way. Thus prevent damage that would occur if they were to get stuck in any moving parts.

Isolators & Knockout boxes

Isolator switches and knockout boxes are added to a mobile gantry in order to protect the equipment and users. They are used for quickly isolating/knocking out all power supply should an issue occur. Sockets connections can also be added.

Crane Accessories

We have a collection of popular crane accessories and lifting equipment to compliment your mobile gantry. Beam trolley, manual chain block and electric hoist options are all readily available from our own trusted Delta range. Typical beam trolley options include a push travel, geared travel or powered travel option. They provide and anchor point for a lifting hoist and enable it to be moved along the beam. Chain blocks or electric hoists are popular hoist options.

The Lifting Gear Store can supply all types of lifting gear to suit your lifting operations, from slings and shackles to lifting clamps and lifting magnets.

Using an A Frame Gantry From Set Up and Safe Use to Maintenance

Set Up;

An A frame gantry is relatively straight forward to set up with the use of a forklift and/or crane as there are only 3 main sections; 2 ‘A’ frames (the side legs) and 1 top runway beam.

A forklift truck is required to lift the runway beam to the necessary height so the A frames can be put into place. This is commonly achieved with a second fork lift or perhaps a crane and sling to raise the leg to vertical (they are heavy, especially the larger models). Ensure castors are locked.

When in position align the holes in the top beam and the side A frame, now insert the bolts and spring washers and secure using the nut. Repeat for the 2nd A frame.

It is wise to double check every bolt before removing any ancillary equipment.

TIP: Fit the beam trolley and hoist to the beam whilst on the fork lift truck prior to the A frames being fitted.

Safe Use of Mobile A frame Lifting Gantries

Planning your lifting operation is essential. Here we provide some basic but tips for using your gantry safely;

ALWAYS

Visually check for defects prior to use looking for distortions in the framework etc.

Check all bolts to ensure they are fully tightened, check the brakes on castors to ensure they are fully functional and check the parking jacks work correctly if fitted.

Castor brakes and parking jacks (if fitted) should always be applied before lifting commences.

Ensure the gantry is level for optimum stability.

Manoeuvre the gantry directly over the load.

Unplug any powered items before moving the gantry to a new position.

All lifting gantries must be thoroughly inspected every year to comply with with LOLER regulations.

NEVER;

Try to move a mobile gantry if it has a load suspended.

Exceed the stated lifting capacity (SWL).

Allow the load to move excessively, don’t let it swing around or rotate.

Walk underneath when a load is suspended.

Use a gantry with suspected or known issues.

Quality Assurance

Our mobile gantries are designed by experts, made in the UK by trained fabricators and experienced engineers. All necessary standards and regulations are met.

Only quality steel and other components are used in the manufacturing process and are inspected and load tested prior to delivery.

We have been manufacturing these mobile A frame gantries for many years and a large portion of our customers are returning ones. Therefore you can be assured that our systems are more than up to the task.

| Capacity Required (A Frame) | 1000KG, 2000KG, 3000KG, 5000KG, 500KG |

|---|---|

| Underbeam Height Required (A frame) | 3 Metres, 4.5 Metres, 5 Metres |

| Span Required ( a frame) | 3 Metres, 4 Metres, 5 Metres |

| Hoist Required (A frame) | No, Yes, Manual, Yes, Electric + Push Travel – 3 phase, Yes, Electric + Power Drive – 3 Phase |