Over Braced Jib Cranes

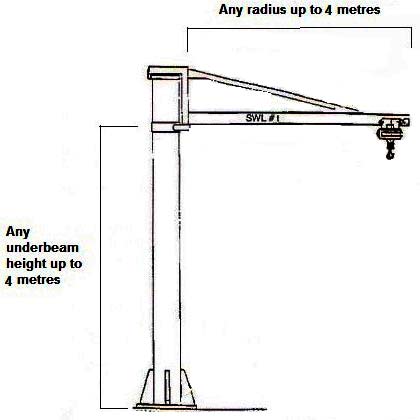

Over braced jib cranes have a different set of pros and cons to under braced models due to the design, however they are available in similar sizes and capacities with the maximum being 4m high x 4m span (model capacity dependant) and up to 3000kg capacities.

Pros and Cons of Over Braced Jib Cranes

It is the arm bracing which makes the difference in these jib cranes. Unlike the under braced jibs the bracing goes over the top, connecting to the top of the upright column then onto the top of the jib arm. Because of this design the actual jib arm is situated lower down the column, thus lowering the maximum height of lift possible whilst requiring a little more headroom for operation.

When it comes to the benefits of over braced swing jib cranes the biggest is probably the fact that the whole length of the arm can be used to traverse equipment and loads, without the hindrance of an under brace. Another benefit is that they are more stable in that there will be minimal deflection/bending because the over brace supports the boom almost to the end, thus distributing the load more evenly. Under braced jibs incur more deflection/bending under the same loading conditions.

The slewing range is the same as for our under braced models, 270 degrees maximum. Slewing stops can be added if required so that the range of rotation is limited to within a specific range, this is typically done to prevent contact with obstacles or reaching into unwanted areas and potentially causing safety issues. If you don’t really need your jib to rotate then we can fix it into position too.

More Customization Options

You will certainly be using some form of beam attachment on your jib crane where you will anchor your lifting hoist. Beam clamps and trolleys can be provided to suit your needs, if you can’t find your desired option available online at the Lifting Gear Store then please get in touch and ask the question, we can usually supply lifting gear for all your requirements. Tell us your size requirements for your custom made over braced jib crane and we will quickly send you an up to date quote.

When it comes to the lifting hoist then we can supply a range of manual hoists like the chain block variety and some great electric hoist options, either stand alone or complete with an integrated trolley.

If you opt for powered equipment then you should consider having the crane pre-wired and add an isolator switch or knockout box and maybe a catenary/festoon system for holding power cables safely. So together with the slew stop limiters there is a great range of optional extras available to customise your jib to suit your needs.

Ancillary Equipment

A jib crane provides the strong framework needed to take the weight of additional equipment and load. Ancillary equipment will be needed to actually lift the load – an electric of manual hoist will be what you need here. If you need to move loads across the jib arm then a beam trolley will be needed. If the hoist can remain in a fixed position then a simple beam clamp will suffice. Some type of beam attachment will be required to attach the hoist securely.

Lifting slings and shackles go hand in hand with many lifting operations so don’t forget to order these if you need them. You should find everything you need at Lifting Gear Store, if not then get in touch, we can usually supply any lifting equipment you may need.